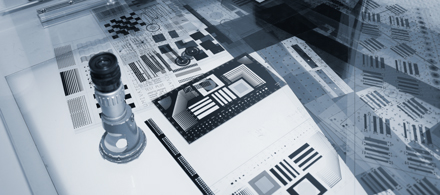

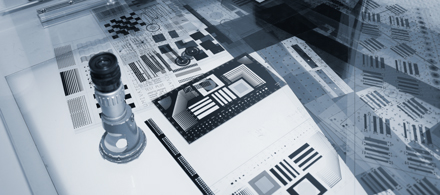

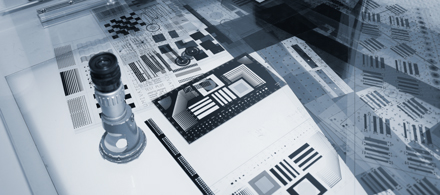

It is important to note that on all MIVA imagers the minimum structure size is directly related but not equal to the projected spot or pixel size. This is because a line or structure is constructed from several pixels which are placed slightly offset to one another. For example, on the MIVA 2025DI, a Direct Imager working in 10.000 dpi mode, the specified minimum structure size is not 2,54 microns (the pixel raster size) but is specified by us at 25microns, because MIVA imagers generally use at least 10 pixels to realise our defined minimum structures in high quality

Resolutions currently available range from 3000 dpi to 128000 dpi.